|

Articles:

Technical Briefs Home

The President's Corner

Molding Compound Lawsuit Quietly

Settled

Lead-Free and the Military / Aerospace

Dilemma

GEIA Hot Solder Dip Specification

Ionic Contamination at the Component

Level

Column Grid Array: The Solution

to BGA Reliability Problems

|

Lead-Free and the Military / Aerospace Dilemma

Beginning in July 2006, the European Union Directive on the restriction of

the use of certain hazardous substances in electrical and electronic equipment

(commonly referred to as RoHS) will be enforced throughout Europe. RoHS

restricts the use of six substances, including lead, which is commonly used in

electronics. Manufacturers outside of Europe will have to abide by RoHS if they

intend to sell electrical and electronic equipment into Europe.

The RoHS directive has succeeded in driving semiconductor and electronics

companies to qualify and adopt lead-free solders.

This is a dilemma for military and

aerospace. They are being forced to use components and processes that are

unproven and, in certain situations, known to be less reliable. Even though

military and aerospace users are exempt from RoHS, the availability of tin-lead

finished components is quickly diminishing and is likely to vanish altogether.

In order to meet the RoHS mandate and minimize inventory costs, semiconductor

and component manufacturers are converting to lead-free solder alloys worldwide.

Almost all components, except Ball Grid Arrays (BGA), are moving to pure-tin

finishes. Ball grid arrays are moving to tin-silver-copper (SAC) alloys.

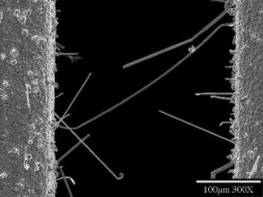

| Pure-tin finishes present a huge problem for the military

and aerospace community. These finishes are known to be prone to tin-whisker

growth. Tin whiskers have caused failures of several weapon and satellite

systems, as well as a nuclear reactor shutdown.

The simplest solution to this tin-whisker dilemma is Hot Solder Dip (HSD).

It can be used to convert pure-tin finishes to tin-lead or lead-free. Hot

solder dipping is a well-established process that has been used in the

semiconductor industry for decades. |

Figure 1: Tin Whiskers [1]

|

The military and aerospace industries face another issue as they try to

incorporate the lead-free BGAs into a tin-lead environment. Studies have shown

that lead-free BGA components are incompatible with tin-lead solders.

The simplest solution to this dilemma is BGA reballing. It can be used to

convert lead-free BGAs to tin-lead.

For more information:

Visit: www.sixsigmaservices.com

E-mail: sales@solderquik.com

Call: 408-956-0100

Six Sigma is actively involved in alloy conversions for military and

aerospace customers. Six Sigma, with its history of providing services for the

semiconductor industry for over 15 years, has proven to be the leader in the

field of hot solder dip,

BGA reballing and

column attach services. During this

time Six Sigma has processed over 20 million components for high-reliability

applications.

Reference:

[1] Galyon, G., J. Smetana and N. Vo (2004). Cause of Tin Whiskers

Remains Elusive [Online]. Available at

http://smt.pennnet.com/Articles/Article_Display.cfm?Section=Articles&Subsection=Display&ARTICLE_ID=216213

(accessed July 31, 2005).

Six Sigma: Subscribe

|