|

SEM - EDS

|

|

| |

Scanning Electron Microscopy (SEM)

|

|

| |

A scanning electron microscope is used to determine the topographical

image or make-up of a sample. It has a greater depth of field, higher resolution

and higher magnification than an ordinary optical microscope. It is relatively

easy to use and is widely-used in almost all research areas. The SEM only produces

high-resolution images of the sample surface. Therefore, the internal structures

of the sample cannot be determined unless a

cross-section is performed.

|

|

|

|

| |

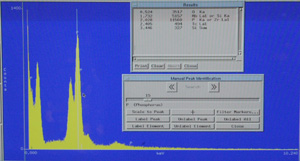

Energy Dispersive Spectroscopy (EDS)

|

|

| |

Energy Dispersive Spectroscopy (EDS) is a standard method of

identifying and quantifying elemental composition of sample surfaces. The characteristic

x-rays are produced when the sample is bombarded with electrons in an electron

beam instrument such as a scanning electron microscope. Detection of these

x-rays and discrimination of the x-ray energies can be accomplished by an energy

dispersive spectrometer.

Suspect Pure Tin on the surface of your part? EDS can

validate your suspicion.

|

|

|

|

| |

Applicable Specifications & Standards:

- ASTM E1829, Standard Guide for Handling Specimens

Prior to Surface Analysis

- ASTM E1508, Standard Guide for Quantitative Analysis

by Energy-Dispersive Spectroscopy

|

|